FERRO SILICON

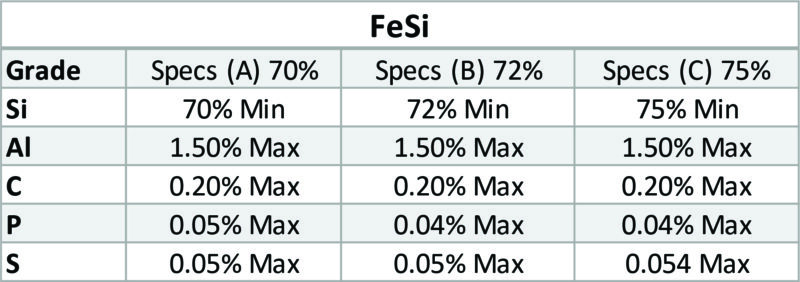

Ferro silicon is indeed a binary alloy of iron (Fe) and silicon (Si). The chemical formula for ferro silicon is typically represented as FeSi. The ratio of iron to silicon can vary, resulting in different grades of ferro silicon. The most common grades include Ferro silicon 75, Ferro silicon 72, and Ferro silicon 70, which indicate the percentage of silicon in the alloy. For example, Ferro silicon 75 means the alloy contains approximately 75% silicon and 25% iron. The chemical composition may also include trace amounts of other elements depending on the source and production process.

- Low-carbon ferro silicon and ultra-low-carbon ferro silicon: These grades of ferro silicon are employed to prevent the reintroduction of carbon during the production of stainless steel and electrical steel.

- Low-titanium (high-purity) ferro silicon: Utilized to prevent the formation of titanium nitride (TiN) and titanium carbide (TiC) inclusions in electrical steel and certain special steels.

- Low-aluminium ferro silicon: This type of ferro silicon is used to avoid the creation of hard aluminium oxide (Al2O3) and aluminium oxide–calcium oxide (Al2O3–CaO) inclusions in various steel types.

- Special ferro silicon: The term “special ferro silicon” encompasses a diverse range of customized products containing additional alloying elements, catering to specific requirements in various applications.

Reviews

There are no reviews yet.